Case-Study: Scanning a truck frame for reverse engineering purposes

In short: Calibry 3D scanner was used to digitize the truck frame in order to reverse engineer it for further custom trailer production.

The aim: Get hi-res scans for precise 3D model

Instruments: Calibry 3D scanner, Calibry Nest Software and Rhinoceros 7.

Achieved results: A 3D model of a frame with minimum deviations was made.

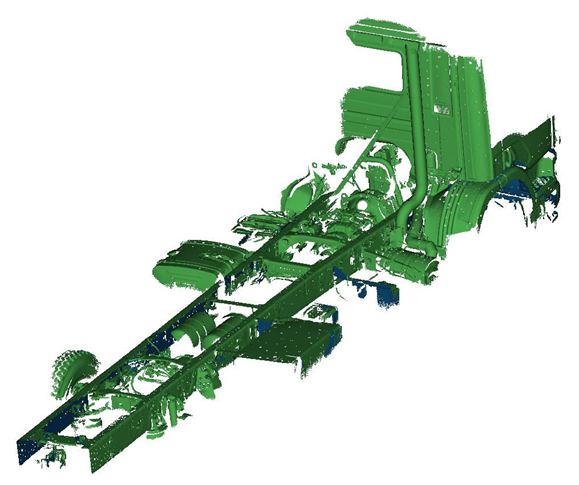

Global 3D has recently carried out an interesting reverse engineering project. Their customer wanted to create a new trailer for Scania truck. To make one, he needed to know where all the connecting elements of the vehicle frame to the new trailer were. Once he knew the exact positioning of all the assembly elements, he could manufacture the trailer, which would perfectly fit with the truck frame. So, the frame had to be scanned by Calibry 3D scanner.

For the reverse engineering purposes hi-res scans were needed, so the specialists applied markers to guarantee optimal scanning result. The preparation (applying markers, calibration), scanning itself and post-processing in Calibry Nest took about 6 hours. As a result, a point-cloud has been created:

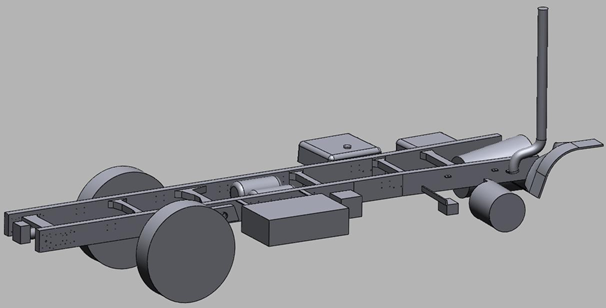

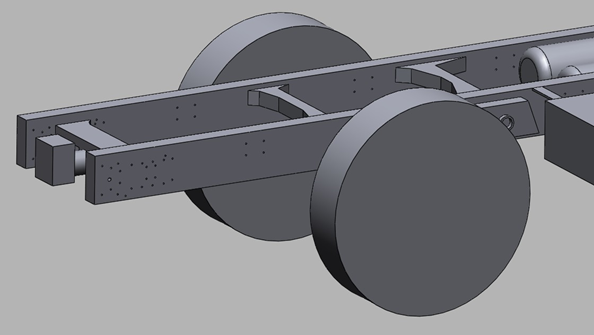

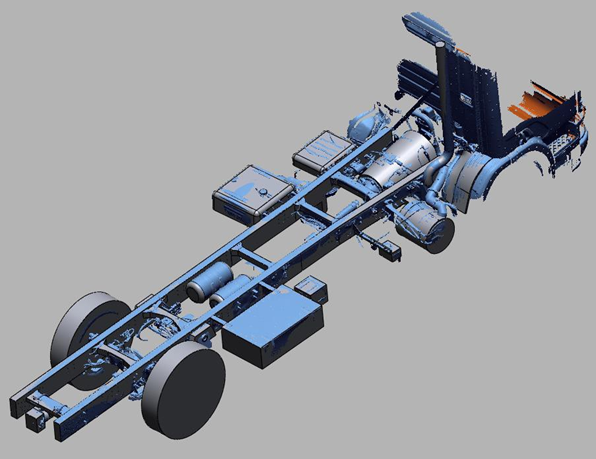

On the basis of the point cloud, a 3D model of the frame was made, containing all the necessary elements and mounting holes. Moreover, the wheels, fuel tank, etc. have been added as a precaution (to make sure that the trailer will fit). The model was made in Rhino 7.

The last stage of the project was to check the compliance of the scan with the model.

The model is ready to be used further on in the custom-made trailer production.