Case-Study: Using Calibry 3D scanner to recreate a broken car part, which is not manufactured any longer

In short: Uniqo Engineering, Thor3D partner in Spain, used Calibry 3D scanner to digitize a motorcar for a client. Then, a broken car part was created.

The aim: Recreate a broken car part which is not manufactured any longer.

Instruments: Calibry 3D scanner, Calibry Nest, SolidWorks, Blackbelt 3D-printer.

Achieved results: The motorcar has been successfully repaired.

When a manufacturer stops producing parts, it always becomes a problem: where can I get the necessary things to fix the broken equipment? A customer asked Uniqo Engineering, Thor3D partner in Spain, to help him repair a broken car part of a motorhome which was no longer produced. They used Calibry to obtain the geometry of both: the original part that is attached to the other side and the motorhome without the part.

Image 1. A motorhome without an original part

Image 2. Another side of a motorhome

The preparation and scanning didn’t take much and the pipeline of the project was quite straightforward:

1. First, the markers were applied because the canning surface was almost completely flat

2. Then the scanning was done, which took 10-15 minutes.

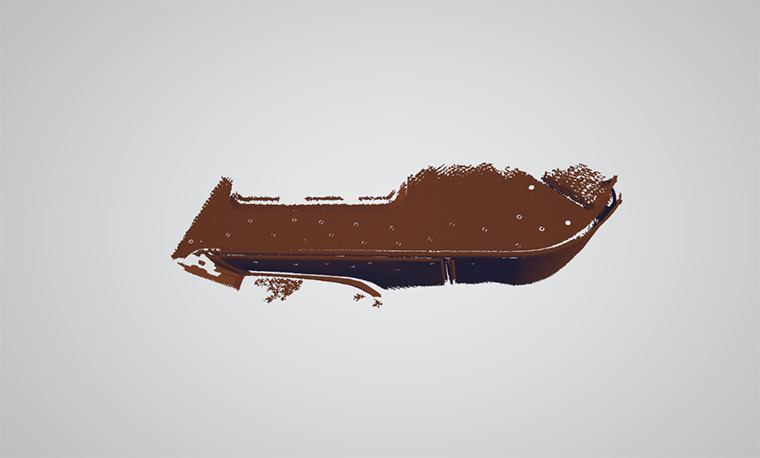

3. The pointcloud was processed in Calibry Nest.

4. Then, the 3D model was turned into a solid body in the SolidWorks software.

Image 3. Scanning the motorhome

Image 4. Scanning the motorhome

Image 5. Calibry Nest. The mesh

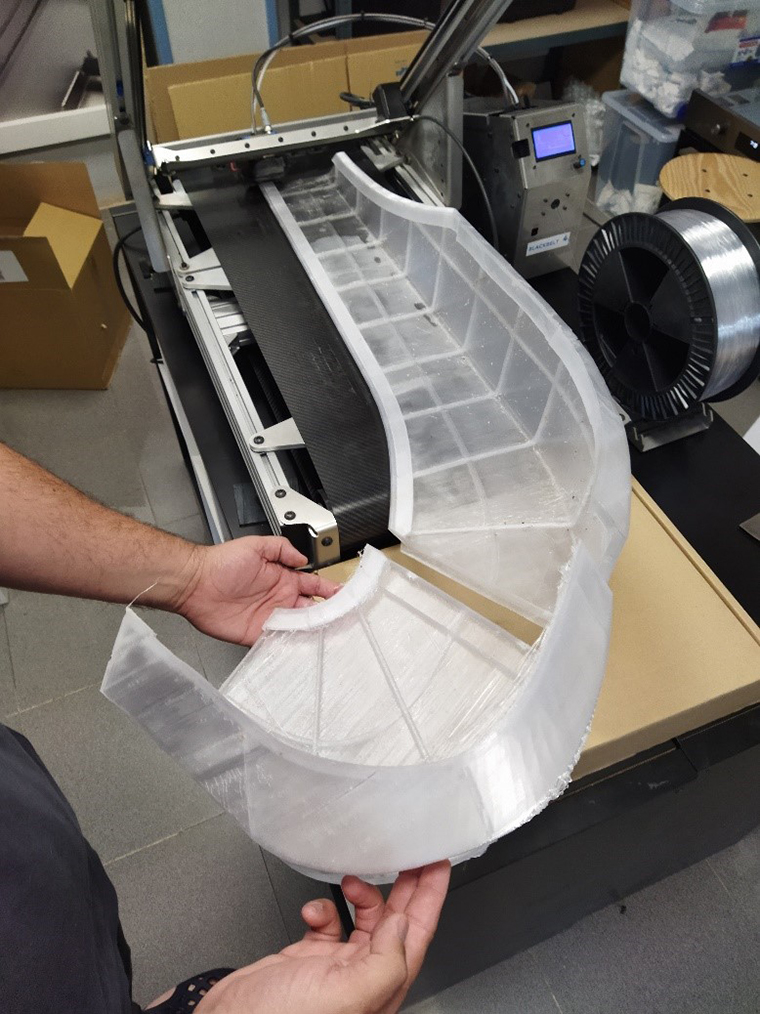

Image 6. New, 3D-printed part

After the model was turned into a solid body, it has been 3D-printed in three parts. All of them took about 48 hours to print as Thor3D partner conveys. Finally, the freshly made car part was finished and ready to be attached to the motorhome.