A 3D scanner is a handy and innovative device for digitizing objects and creating their replicas. As the manufacturer of 3D scanners, we often advise clients on how to use our equipment effectively. Over the years, we’ve seen some truly bizarre objects people have tried to scan: internal organs, live fish, robot parts, tree stumps... There have been models, athletes, works of art, and monumental sculptures. Indeed, we could write a whole entertaining article just listing these examples. Inspired by these quirky experiences, we decided to share a few things that make no sense to scan—but people keep trying anyway.

Anything That Moves Uncontrollably

To create a high-quality digital model, the object needs to be still. That’s why scanning people, especially their body parts for prosthetics or orthopedics, is a tricky task. People even invent special supports to stabilize a person and minimize unintentional movement. Let’s face it: most of us find it hard to stay perfectly still for a minute.

Nevertheless, scanning an adult—or even a fidgety kid—is doable. But pets? Forget it. Good luck explaining to your cat the importance of sitting still for a 3D scan to be made, which later will be turned into a polygonal model and sent to a 3D printer. At best, you’ll get a disdainful stare; at worst, scratched hands.

Liquids, moving fabrics, long and thin hair also cannot be scanned - on the computer screen they turn into a chaotic cloud of dots, unsuitable for further processing.

Don’t Overcomplicate When Traditional Methods Are Faster

There’s no need to make things harder than they are. For example, one logistics company planned to use a 3D scanner to measure boxes. Sounds fresh and innovative, right? Except using a tape measure was way simpler and faster than taking a 3D scanner, connecting it up to a laptop, finding a power source, loading the data into software, and processing the point cloud...

On a related note, 3D scanners aren’t always the best choice for reverse engineering either. Unless it’s a specific case, there’s little point in using a scanner for simple objects like tables or stools with flat surfaces when you could just draw them from scratch.

In our experience, there was a case when some designers planned to use a 3D scanner to measure a kitchen (countertop and wall) for installing a stove. If the space has simple geometry, just grab that trusty old tape measure.

Don’t Try to Defy the Laws of Physics

As the saying goes, “There are three things you can watch forever: fire, water, and a serial tinkerer trying to outsmart the merciless laws of physics.”

Transparent objects can’t be digitized directly because light passes right through them. If a transparent part is included in the scanned object, we coat it with a matte spray. When scanning a car, we “dust” the windshield, rear, and side windows so the scanner can capture their shape.

In our practice, we’ve seen unsuccessful attempts to scan ice and snow. To clarify the task: the goal wasn’t just to measure a chunk of ice but to fully capture its physical properties, like transparency...

Don’t Bother Scanning Soft, Flexible, or Deformable Objects

This point somewhat ties back to the first one about moving objects. Items that change shape in space are also tough to scan well (unless you figure out a way to stabilize them). Think long plastic parts that sag under their own weight, orthopedic pillows, or anything else with unstable geometry.

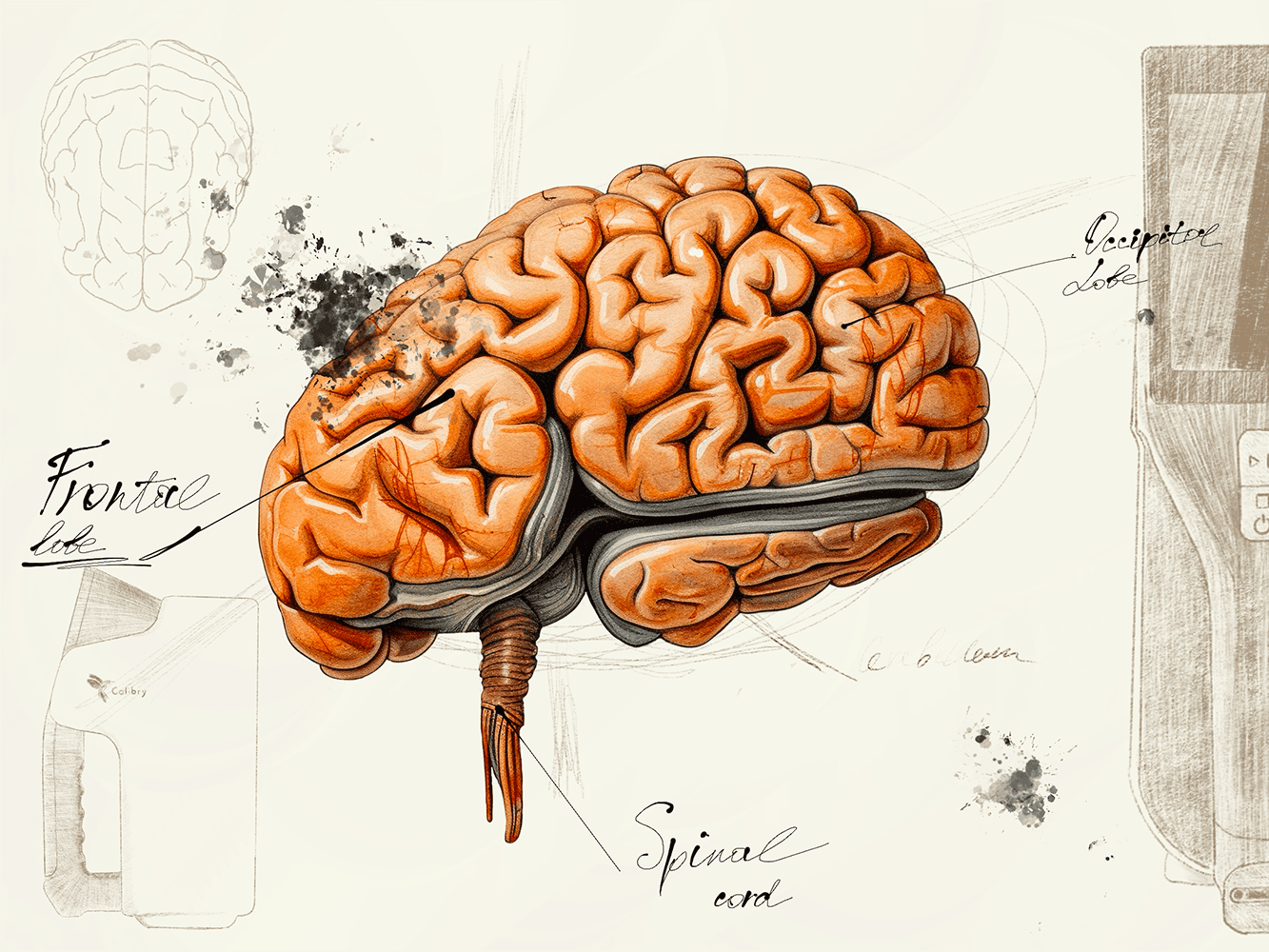

In our experience, there was a case of scanning a brain for medical purposes. An unprepared organ, due to the nature of its tissue, might not come out clear enough. However, a brain stabilized in formalin scans beautifully. If the goal is to create detailed 3D models of internal organs, you need to figure out how to stabilize them first. In general, deformable objects are tough to scan, and in most cases, it’s easier to recreate their copies in modeling software.

To sum up, 3D scanners are a powerful tool for creating digital replicas, but they require specific skills. Instead of overcomplicating things, ask yourself: wouldn’t a traditional method be faster and cheaper? At the same time, objects with complex geometry, architectural elements, or unique details are where 3D scanning truly shines.