Historically, engineers relied on dimensional measuring tools such as calipers, micrometers, height gauges, and protractors. However, each tool had its limitations. The introduction of Coordinate Measuring Machines (CMMs) streamlined measurements, but CMMs also have drawbacks: they are slow at measuring complex geometries, require direct physical contact, struggle with hard-to-reach areas like deep cavities or undercuts, and have complex setups with limited scalability for large objects.

Metrological 3D scanners represent the next generation of measurement tools for quality and accuracy control. Widely used in production facilities, they rapidly digitize objects, offer portability in many models, and produce scan data compatible with leading engineering software.

What Metrology Scanners Are Available on the Market?

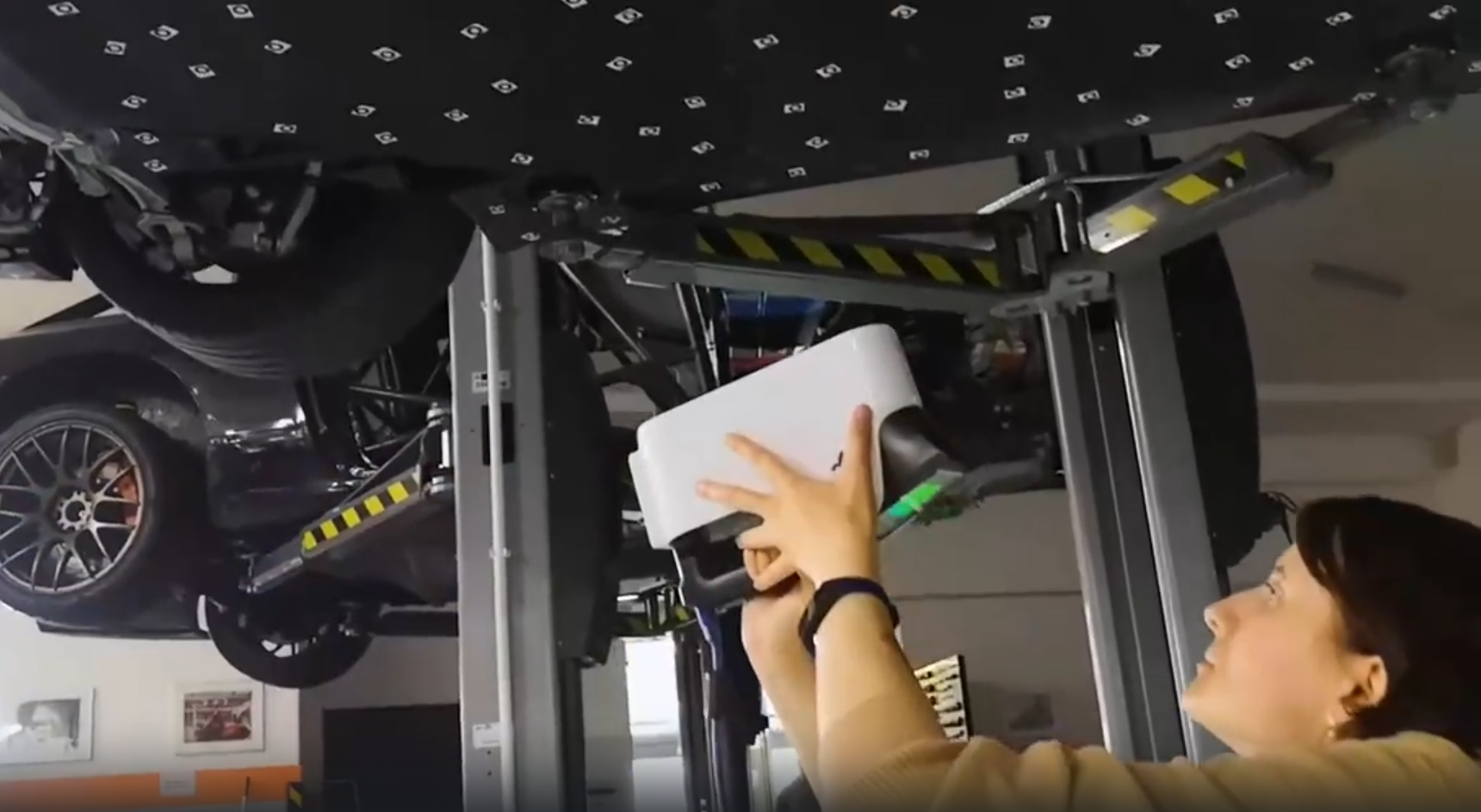

3D scanners vary in portability (stationary vs. handheld) and scanning technology. These factors are critical when selecting a scanning device.Handheld scanners are lightweight and versatile, making them ideal for scanning in tight spaces or on-site. For example, they can digitize components under a car, scan a small tool brought to your office, or capture industrial objects at remote locations.

Stationary scanners, mounted on tripods or robotic arms, are better suited for lab environments or assembly lines. Though less flexible, they excel in repetitive, high-volume tasks.

The scanning technology is another key consideration:

- Structured Light (Blue/White Light): These scanners project light patterns to capture surface data. They are fast, highly accurate (approximately 0.07-0.1 mm), and cost-effective, making them suitable for both static and handheld applications.

- Laser Triangulation: These scanners use laser lines to measure objects. Known for superior precision (down to 0.02 mm), they are ideal for miniature industrial applications. However, high-precision laser scanners can be expensive.

Features to Consider in Metrology 3D Scanners

Understand Your Metrology Requirements

Consider your working conditions when choosing a metrological scanner. Will you scan indoors at a fixed location, or do you need portability for various sites? What types of objects will you digitize? Are they consistently sized miniature industrial parts, or do they vary in size and shape with hard-to-reach areas, such as turbine blades with intricate features?

Accuracy and Resolution

Accuracy and resolution are the core specifications in metrology. Accuracy indicates how closely the scanner’s measurements match the object’s true dimensions, while resolution reflects the smallest detail the scanner can capture.

While high accuracy and resolution may seem universally desirable, they should be chosen thoughtfully. For large objects (e.g., 5 meters in length) used in quality control, an accuracy of 0.1 mm and a resolution of 0.6 mm may suffice. If the object lacks intricate details, investing in ultra-high precision is unnecessary, saving both budget and computing power.

Conversely, small objects (e.g., 5 cm in length) with patterns, hollows, or bulges require greater precision. A scanner with an accuracy of about 0.07 mm and a resolution of 0.15 mm can produce a high-resolution 3D model. Tiny objects, just a few millimeters long, demand even higher precision, which laser scanners can provide.

Software

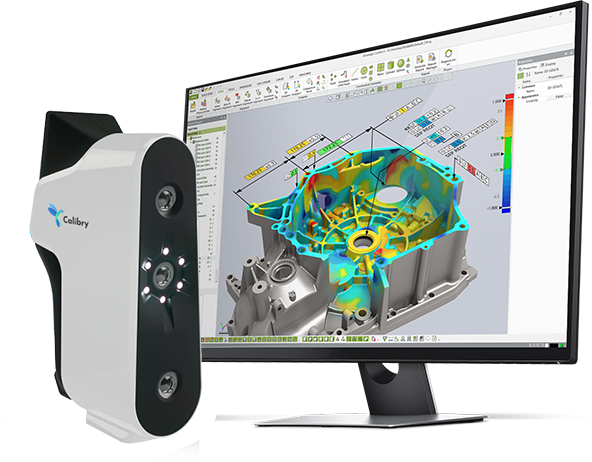

A scanner’s hardware is only part of the equation – software transforms raw data into actionable insights. Metrology applications require:

- Real-time Mesh Generation: Visualize the model during scanning to identify errors early.

- Inspection Tools: Compare scans to CAD files for deviation analysis (e.g., color maps showing tolerances).

- Compatibility: Ensure integration with existing tools like SolidWorks.

Some manufacturers bundle CAD software, providing a comprehensive solution for clients.

Other Important Considerations When Choosing a 3D Scanner

Hidden Costs

Beyond the scanner’s purchase price, consider potential hidden costs:

- Training and setup expenses.

- Maintenance, such as calibration.

- Accessories, including backpacks, markers, or tripods.

- Software licenses or upgrades.

A $5,000 budget might secure a reliable handheld scanner with basic software, but high-end automated systems can exceed $100,000.

Vendor Support

Metrological 3D scanners are complex, costly devices. At the outset, you may encounter numerous questions, making vendor support a critical factor. Does the scanner come with a warranty? Does the supplier offer technical assistance? Local distributors or responsive support teams are essential for troubleshooting. Can you test a demo unit? We recommend evaluating the scanner with your parts/objects before committing.Purchasing a 3D scanner for metrology is an investment in precision and efficiency. Begin by aligning the scanner’s capabilities with your objects, tolerances, and workflow. Prioritize your specific needs over flashy features and insist on testing. Whether you’re measuring small components or large assemblies, the right scanner will enhance accuracy and streamline operations.