3D scanning is becoming increasingly popular in various industries because it makes measurement and digitization of objects very easy. 3D scanners help facilitate the production of broken or lost parts. They are also very popular in auto repair and car tuning.

3D-scanners may help in the restoration of cultural heritage (digitizing dinosaur footprints in Poland, or reconstructing The Tower Hill Memorial).

Body scanning is popular in prosthetics and sports. The entertainment industry is also actively mastering 3D technologies.

But there is still some confusion about what the difference between a scan and a CAD model is. Is a 3D-scan enough for industrial applications, or is it necessary to edit the model?

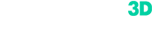

A 3D scanner is a device that makes a digital copy of a real-life object. In order to make a copy of an object, the scanner projects LED light onto its surface, which creates a light grid and collects the data (the points). Thus, a 3D-scan is a point cloud converted into a polygonal model.

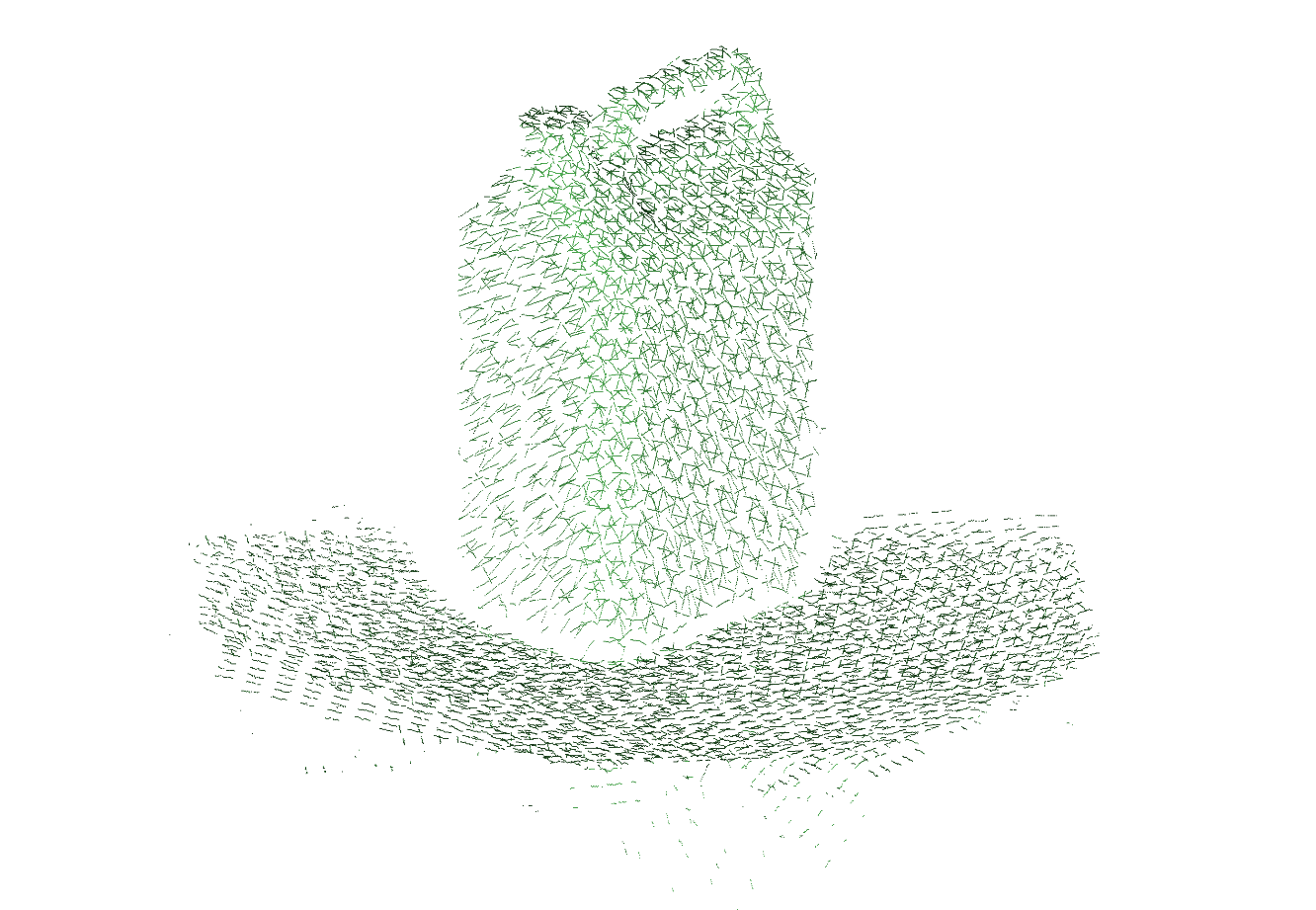

3D-scans are formed out of polygons and come in the following formats: .stl, .ply, .obj. It’s important to note, that the polygonal models are not necessarily the ones obtained by 3D-scanning. Designers, constructors and visual artists also use polygonal models in their work. Those models are made in special programs. Polygonal modeling is heavily used in the interior design construction, as well as 3D graphics and VFX.

In order to apply a 3D scan for downstream use, it must be converted into the appropriate format supported by 3D-printers, CNC machines, or other equipment or software in which the model will be used. You can prepare models for the appropriate format directly in the software in which a 3D scan is processed (for example, Calibry Nest).

For 3D printing, the model must be watertight, while for CNC milling its surfaces will also have to be smooth.

Polygonal models need slight editing because the mesh of the surface is not perfectly smooth and has holes sometimes. While this requirement is not so important for 3D printers, rough mesh can be disastrous for the CNC machine. If a 3D scan will be used for prototyping, it will also need to go through slight preparations.

However, if a polygonal model will be used for production or engineering purposes (for example it is necessary to recreate a new part to replace a broken one), then most likely it will be converted into CAD format, which is also called solid modelling.

In solid modelling, an engineer creates a mechanical part out of solid primitives partially imitating manufacturing process (extruding, drilling). Solid modelling is parametric, meaning that the change of one parameter inevitably leads to the changes in the adjoining ones. The model has a parametric history (the tree) and the engineer can always trace back to the previous stage of the model and change it.

Another significant feature of solid models is that the specialist can set the exact size of both the model itself and its individual parts. This is especially important if it is necessary to strictly follow the drawing. Such manipulations are not possible in polygonal modeling.

It is not easy to convert a polygonal model into a solid one. The more complex the model, and the greater the accuracy requirements are, the more time it will take.3D-scans are formed out of polygons and come in the following formats: .stl, .ply, .obj. It’s important to note, that the polygonal models are not necessarily the ones obtained by 3D-scanning. Designers, constructors and visual artists also use polygonal models in their work. Those models are made in special programs. Polygonal modeling is heavily used in the interior design construction, as well as 3D graphics and VFX.

In order to apply a 3D scan for downstream use, it must be converted into the appropriate format supported by 3D-printers, CNC machines, or other equipment or software in which the model will be used. You can prepare models for the appropriate format directly in the software in which a 3D scan is processed (for example, Calibry Nest).

For 3D printing, the model must be watertight, while for CNC milling its surfaces will also have to be smooth.

Polygonal models need slight editing because the mesh of the surface is not perfectly smooth and has holes sometimes. While this requirement is not so important for 3D printers, rough mesh can be disastrous for the CNC machine. If a 3D scan will be used for prototyping, it will also need to go through slight preparations.

However, if a polygonal model will be used for production or engineering purposes (for example it is necessary to recreate a new part to replace a broken one), then most likely it will be converted into CAD format, which is also called solid modelling.

In solid modelling, an engineer creates a mechanical part out of solid primitives partially imitating manufacturing process (extruding, drilling). Solid modelling is parametric, meaning that the change of one parameter inevitably leads to the changes in the adjoining ones. The model has a parametric history (the tree) and the engineer can always trace back to the previous stage of the model and change it.

Another significant feature of solid models is that the specialist can set the exact size of both the model itself and its individual parts. This is especially important if it is necessary to strictly follow the drawing. Such manipulations are not possible in polygonal modeling.

It is not easy to convert a polygonal model into a solid one. The more complex the model, and the greater the accuracy requirements are, the more time it will take.To sum up: a 3D scan is represented as a polygonal mesh and a CAD model as geometric solid primitives. These models have different formats and contain different information about the object.

Since a 3D scan is essentially a polygon mesh, it doesn't contain information about sharpness of the object’s edges. When you zoom in on the model, you will see that many polygons are "rounded off", smoothing out the surface. This may be insignificant if you use the model in sculpting, but it is not acceptable for industrial purposes.

Unlike polygonal models, CAD models contains all necessary information about the object (where the sharp edges should be, wall thicknesses, etc.).

To sum up: a CAD model consists of geometric solid primitives, which gives full freedom in working with the model. A specialist can control its size and tolerances, at any time go back to earlier versions of the model and make appropriate changes. CAD models contain no superfluous information and display data about the object correctly (no smoothed corners where it is not necessary). CAD models are compatible with all 3D printers and CNC machines.

In many cases, 3D scans are quite suitable for subsequent use after light retouching. However, a polygonal model needs to be converted into a parametric format for a number of production/engineering tasks.

So, in what cases can a polygonal model be used and when a CAD model is needed? Unfortunately, there is no universal answer. For an individual specialist the technical characteristics of a part may not be important, and he will send a polygonal model straight to the 3D printer in the .stl format. In another case, the accuracy of dimensions can be crucial. The need for Scan-to-CAD conversion is purely individual and depends on the end goals.